Canon U.S.A. Announces Mobile Printing App for Home and Office Users

New App for iPhone® and iPad® Enables Efficient, Intuitive Mobile Printing to a Wide Range of Canon Devices Including select imageCLASS Printers, imageRUNNER ADVANCE and imageRUNNER Office Systems and imageRUNNER LBP Printers

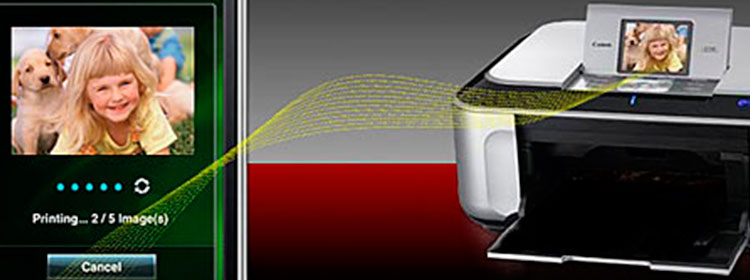

LAKE SUCCESS, N.Y.–(BUSINESS WIRE)– Canon U.S.A., Inc., a leader in digital imaging solutions, today announced its Canon Mobile Printing App for iPhone® and iPad®, extending Canon’s already comprehensive support for mobile office users and consumers. Canon Mobile Printing enables users in homes and offices of all sizes to send print jobs directly from their iPhone and iPad to a compatible Canon output device.

The Canon Mobile Printing App is compatible with select Canon imageCLASS desktop laser printers and multifunction printers including the recently launched MF4000 models. The app is also compatible with Canon’s recently released next generation imageRUNNER ADVANCE C5200, 6200, and 8200 enterprise multifunction office systems. Additionally, the app supports most imageRUNNER and imageRUNNER ADVANCE enterprise multifunction office systems, as well as imageRUNNER LBP printers. Users can print Microsoft ® Office files (doc, docx, xls, xlsx, ppt, pptx), iWork® files (Pages, Numbers, Keynote), JPEG, GIF, BMP, PNG, TIFF and PDF files, photographs (stored in Photo Albums and taken with the device camera), and web pages directly through the app’s user-friendly interface.

“With today’s mobile workforce, being able to print on-the-go is becoming an increasingly valuable asset,” said Sam Yoshida, vice president and general manager, Marketing, Business Imaging Solutions Group, Canon U.S.A. “The new Canon Mobile Printing App provides ease of use and places traditional print functionality at the fingertips of today’s mobile worker.”

The Canon Mobile Printing App features the following innovative tools:

OpenIn Compatibility Improves Efficiency

The Canon Mobile Printing user experience becomes seamless with the integration of OpenIn, a feature that allows users to capitalize on the functionality of the mobile app while navigating through files located elsewhere. The OpenIn feature allows users to easily navigate to Canon Mobile Printing directly from the application they are in, giving the customer more ways to access printing.

Variety of Supported Document Types Enhances Usability

Designed with the end-user in mind, the app supports a variety of file formats. Users can print Microsoft Office files (doc, docx, xls, xlsx, ppt, pptx), iWork files, PDF, JPEG, GIF, BMP, PNG, TIFF files, photographs, and web pages can be printed directly through the app.

Wide Range of Compatibility Provides a Satisfying End-User Experience

The app supports devices running iOS 5.1 – 6.0 and is available for the iPhone 5, iPhone 4S, iPhone 4, the new iPad, iPad 2, and the original iPad. The app also supports most imageRUNNER and imageRUNNER ADVANCE enterprise multifunction office systems and includes support for the next generation imageRUNNER ADVANCE multifunction devices. In addition, the app supports compatible imageCLASS printers and imageRUNNER LBP printers.

Intuitive Printer Communication

The app can search for and identify Canon printers within a wireless (Wi-Fi) broadcast range – and automatically save these devices for future use. If the Canon printer cannot be found within a wireless broadcast range, users can manually enter the IP address of the Canon device to list it as one of their available print devices.

Opportunity to Choose Print Settings Optimizes Workflow

The app offers a variety of built-in printing options to enhance control and performance. Users can tailor print range, paper size, color output, and number of copies directly from the app. Depending on the finishing features on the printer, documents can also be stapled directly from the menu. Additionally, users can instruct the app to feed paper automatically or via the device manual bypass.

Preview Modes Support Enhances Ease of Use

Users will be able to preview documents, photos and web pages prior to printing to determine the ideal settings for a specific print job. Items with multiple pages can also be previewed by swiping the screen to move through the document.

The Canon Mobile Printing App is available for free from the App Store℠ or atwww.itunes.com/appstore. Search for “Canon Mobile Printing”.

For product specifications and device information, please visit the Canon USA website athttp://usa.canon.com/cusa/office/standard_display/DeviceListing

origanal article

Like this:

Like Loading...